ALUGEAR Cranks: Certified Reliability, Superior Performance, and Exceptional Durability under ISO 4210-8:2023

Mountain biking demands components that are not only lightweight but incredibly robust, capable of withstanding extreme stresses and conditions. ALUGEAR, renowned for its innovative and reliable bicycle components, sets itself apart with crank systems rigorously tested to meet and exceed international safety and performance standards, particularly the stringent ISO certifications.

Comprehensive ISO Standards for Reliable Components

ALUGEAR ensures the reliability of its cranks through adherence to rigorous international standards, specifically DIN EN ISO 4210-2:2023-05 and DIN EN ISO 4210-8:2023-05. These standards are internationally recognized for establishing benchmarks in bicycle safety, durability, and overall product integrity. Such stringent compliance assures riders of the exceptional quality and longevity of their bicycle components, especially critical elements like cranks, which endure significant mechanical stresses.

Simulation and Real-world Pre-testing

Prior to the ISO certification tests, ALUGEAR conducts extensive simulation tests using advanced computer modeling and virtual stress-testing techniques. These preliminary simulations allow engineers to anticipate potential structural weaknesses, optimize designs, and ensure each crank model is ready to face rigorous physical testing. This proactive approach dramatically increases product reliability and performance before the components even enter official testing phases.

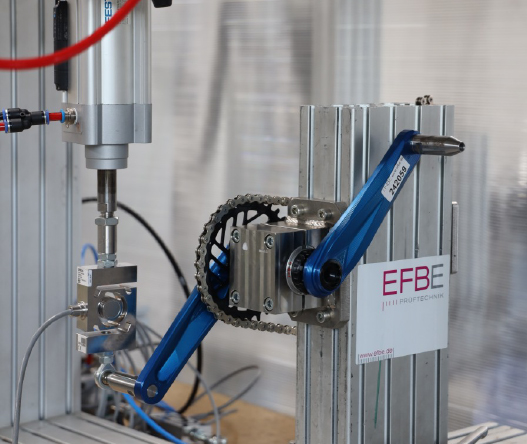

Advanced Testing Techniques Using Dedicated Machines

ALUGEAR employs comprehensive fatigue testing protocols that simulate real-world riding conditions, particularly focused on two critical scenarios riders frequently encounter:

1. Fatigue Testing with Cranks at 45° to the Horizontal

This rigorous fatigue test closely replicates the mechanical stress and strain experienced during normal pedaling actions. Each crank undergoes:

-

50,000 load cycles applied to the drive side crank arm, subjected to a dynamic force of 1,845 N.

-

Another 50,000 load cycles on the non-drive side crank arm at the same intense force level.

Such extensive testing ensures each crank's ability to endure continuous, repetitive pedaling forces without failure. The ALUGEAR Cranks have impressively completed these demanding tests, demonstrating no visible cracks, fractures, or structural weaknesses after a cumulative total of 100,000 cycles, validating their robust construction and exceptional durability.

2. Fatigue Testing with Cranks at 30° to the Horizontal

Recognizing the dynamic conditions riders encounter during aggressive downhill maneuvers or when standing on pedals to leverage steep descents, ALUGEAR implements another essential test. Conducted at a 30° angle to the horizontal plane, this procedure subjects the cranks to significant downward forces that simulate aggressive, weight-intensive riding scenarios. Successfully passing this demanding test further attests to the crank arms' capacity to handle intense pressures and dynamic loads, reassuring riders of their safety and the crankset’s lasting integrity even under extreme conditions.

Extreme Real-world Rider Testing

After successfully passing machine-based fatigue tests, ALUGEAR Cranks undergo extensive field tests conducted by professional riders across various mountain biking disciplines, from Cross-Country and Enduro to extreme Downhill challenges. Our riders push the cranks to their limits in harsh terrains, rocky trails, steep descents, and high-speed jumps. During these intense real-world trials, cranks are subjected to the relentless impacts and stresses that competitive and extreme riders frequently encounter.

In extreme Downhill scenarios, ALUGEAR Cranks have endured spectacular drops, punishing rock gardens, and high-impact landings without compromising structural integrity. Riders confidently execute daring maneuvers, knowing that their ALUGEAR Cranks can absorb severe shocks and maintain peak performance even under the harshest riding conditions. These extensive field tests validate not only the durability but also the exceptional reliability and resilience of ALUGEAR Cranks in real-world mountain biking scenarios.

Precision Engineering and Material Excellence

Beyond rigorous testing, ALUGEAR Cranks embody cutting-edge engineering principles and superior material choices. Utilizing premium-grade aluminum alloys, each crank is designed for an optimal balance of lightweight efficiency and remarkable strength. ALUGEAR's engineering practices involve meticulous attention to detail, precision machining, and advanced manufacturing processes. This approach results in crank arms that not only excel in performance but also maintain resilience and durability through countless hours of challenging terrain and demanding cycling.

Conclusion: Confidence and Performance Combined

With ALUGEAR Cranks, riders experience peace of mind, knowing their equipment can handle the rigorous demands of mountain biking while delivering exceptional performance. Trust ALUGEAR—where innovation meets precision, and exceptional performance meets certified reliability.

Comments

No comment at this time!

Leave your comment