CNC Machining vs. 3D Printing: Alugear's Advanced Manufacturing Approach

At Alugear, we embrace both CNC machining and 3D printing technologies to deliver exceptional cycling components. Each technology offers distinct strengths, and combining them allows us to provide superior quality and innovation tailored to your cycling needs. As the cycling industry evolves, Alugear increasingly utilizes advanced 3D printing methods to complement our precise CNC machining processes.

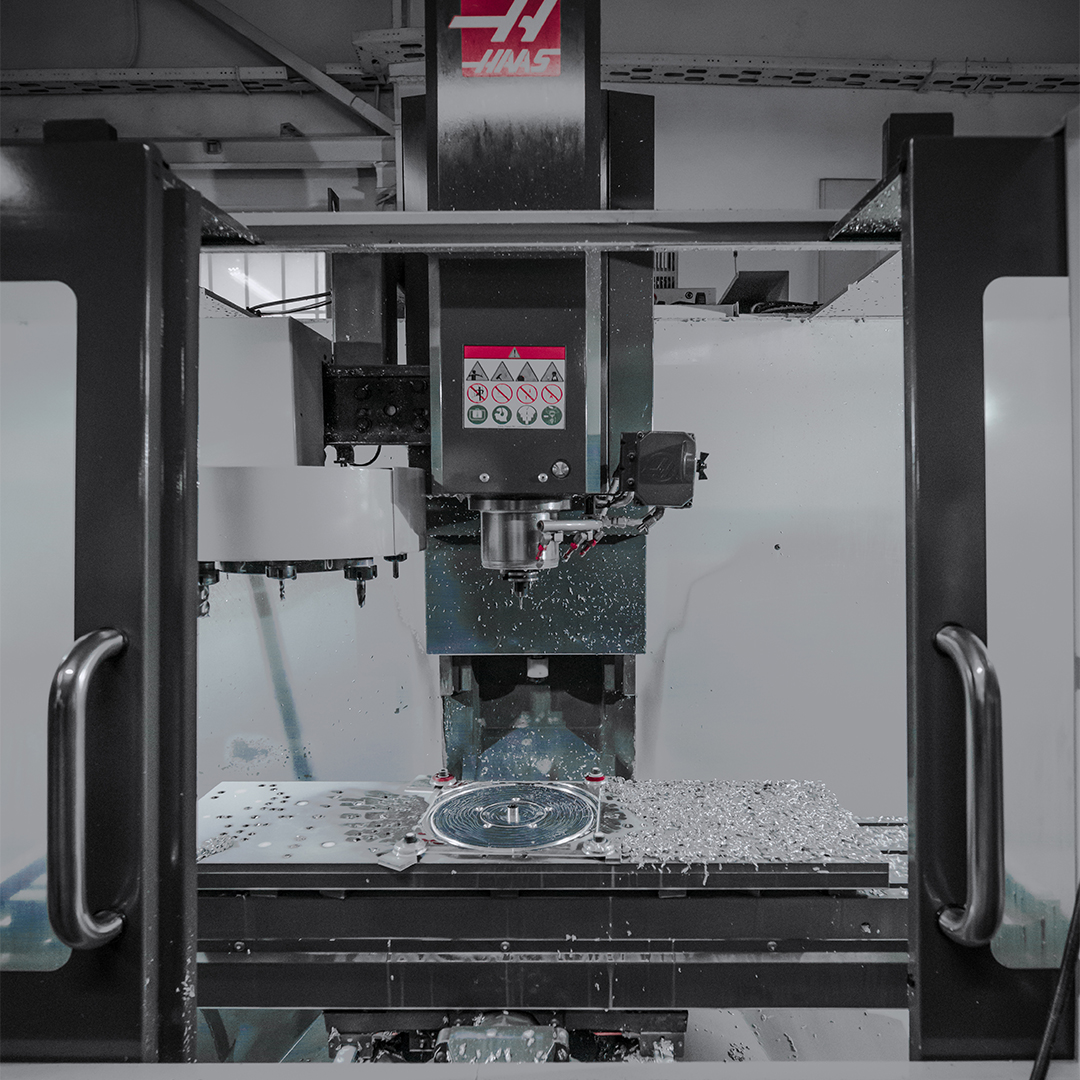

What is CNC Machining?

CNC (Computer Numerical Control) machining is a highly accurate subtractive manufacturing process that shapes components from a solid block of material by systematically removing excess material guided by advanced software. Alugear leverages state-of-the-art CNC technology to produce cycling components with remarkable precision and durability.

Key Stages of CNC Machining:

- Design: Creating precise CAD models tailored for cycling performance.

- Setup: Configuring CNC machines with specialized tooling and premium materials.

- Execution: CNC machines mill and turn components precisely according to digital specifications.

- Quality Check: Rigorous inspections ensure Alugear’s high-quality standards.

Advantages and Limitations of CNC Machining:

Advantages:

- Exceptional accuracy and precision

- Effective for complex and robust cycling components

- Ideal for large-scale production

- Compatible with various materials, including lightweight alloys used in cycling

Limitations:

- Higher initial setup costs

- Generates some material waste

- Requires specialized operators

- Less effective for ultra-intricate geometries

What is 3D Printing?

3D printing, or additive manufacturing, constructs parts layer-by-layer directly from digital models, enabling innovation in complex geometries and customizations. At Alugear, we increasingly utilize 3D printing for rapid prototyping, custom parts, and intricate components that enhance cycling performance.

Key Stages of 3D Printing:

- Design: Digital CAD models optimized for additive manufacturing.

- Preparation: Selection of specialized printing materials and precise printer configurations.

- Printing: Layer-by-layer construction optimized for performance and lightweight designs.

- Post-processing: Finishing processes to ensure component reliability and aesthetics.

Advantages and Limitations of 3D Printing:

Advantages:

- Ideal for complex and innovative geometries

- Highly effective for prototyping and customization

- Minimal material waste

- Lower initial costs for smaller production runs

Limitations:

- Limited material selection compared to CNC

- Generally lower precision and surface finish than CNC machining

- Less efficient for high-volume production runs

- Often requires detailed post-processing

Comparing CNC Machining and 3D Printing at Alugear:

Material Compatibility:

- CNC machining allows Alugear to utilize diverse premium materials, including high-performance aluminum alloys.

- 3D printing primarily employs specialized plastics, resins, and select metal powders suitable for innovative cycling solutions.

Precision and Surface Quality:

- CNC machining delivers superior precision and exceptional surface quality, ideal for high-performance cycling components.

- 3D printing provides adequate precision for complex and custom-designed components, continually advancing in accuracy.

Design Complexity:

- 3D printing enables Alugear to push boundaries with complex and innovative designs difficult to achieve with CNC.

- CNC machining excels in precise external geometries and structural components.

Production Volume and Speed:

- CNC machining efficiently handles Alugear's large-scale production needs.

- 3D printing optimizes rapid prototyping, custom components, and small-batch production.

The Future: Combining CNC and 3D Printing for Optimal Results at Alugear:

We believe in the synergy of CNC machining and 3D printing.

By integrating both methods, we:

- Rapidly prototype using 3D printing, quickly iterating and refining designs.

- Transition proven designs into CNC production for scalable, efficient manufacturing.

- Employ hybrid manufacturing methods, using CNC to enhance precision and finish on 3D-printed components.

As the cycling industry progresses, Alugear remains committed to leading with innovation, increasingly adopting 3D printing alongside our proven CNC machining expertise to deliver exceptional, future-ready cycling components.

Comments

No comment at this time!

Leave your comment